Designed for transferring rolling stock from one track to another at metallurgical enterprises. The translation is made on the basis of the LPTP.665121.103M project, but is intended for welding into a continuous welding path using an electric contact welding machine. A counter-rail protector made of rolled rails is installed in the front extension of the switch. Three connected stripes are installed on the arrow. The crosspiece is made as a monoblock, rail ends in the front and rear overhangs are welded to a cast core made of high-manganese steel, and rail guards made of rolled rails are attached with horizontal bolts. The counter-rail of the crosspiece is made of rolled rails. All linings have high flanges. The blades and frame rails are HDTV hardened.

| Type of turnout | ordinary |

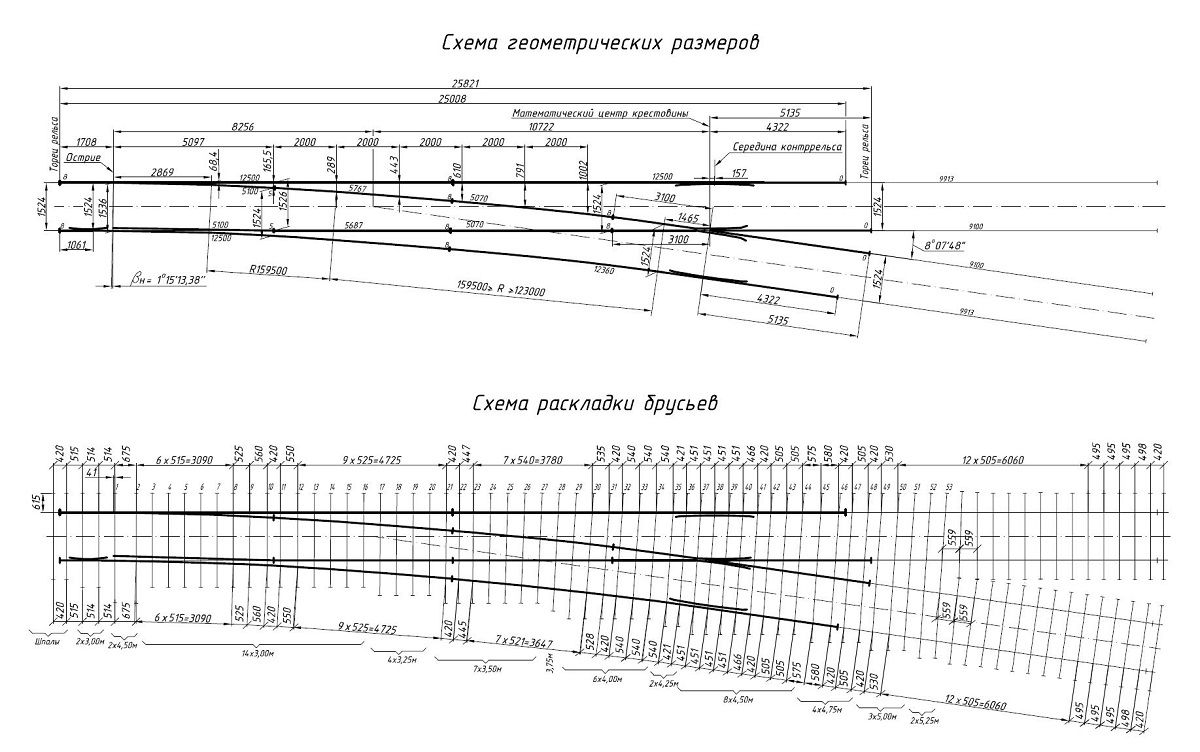

| Track width, mm | 1524 |

| Total length, mm | 25821 |

| Side path radius, mm | |

| arrows | 159500 |

| conversion curve | 159500 with transition to 123000 |

| Maximum static load on rail, kN | 320 |

| Maximum speed, km/h | |

| along the straight path | 50 |

| along the side path | 30 |

| Standard resource before switch removal, million tons | 70 |

| Maximum length of shipping space, mm | 12500 |

| Maximum weight of shipping item, t | 2,1 |

| Weight (without bars), and no more | 11,5 |